The difference between amateur and professional marine operations comes from the accessories that support, protect and enhance rope performance, not just the rope materials themselves. Safe vessel operations start with high-quality boat dock lines, but accessories determine whether the system performs dependably or fails prematurely.

Marine rope accessories play a crucial role in the performance of rope systems in professional maritime operations.

Professional mariners recognize that rope performance depends on more than fiber quality and manufacturing methods. The marine environment creates challenges that can damage even premium ropes without proper protection. Salt exposure, UV light, constant movement, and abrasive contact points all contribute to rapid deterioration.

The rope and marine supply industry now considers accessories essential components of professional rope systems. Investing in quality accessories extends rope lifespan, improves safety, and reduces maintenance demands.

Chafe Protection: The First Line of Defense

Chafe damage is the primary cause of premature rope failure. Abrasive contact with cleats, chocks, dock hardware, and rough surfaces weakens rope integrity faster than any other factor.

American Rope offers advanced chafe guard solutions engineered for superior durability and UV resistance. These guards create a protective barrier against abrasion, with reinforced stitching and materials designed to resist saltwater damage.

Modern synthetic chafe guards provide better durability and UV protection than traditional materials. Heavy-duty nylon covers, polyurethane sleeves, and specialized polymer guards deliver strong protection while staying flexible.

The most durable chafe protection comes from rigid systems. Plastic tubes combined with composite guards act as hard barriers that deflect abrasive forces rather than absorb them.

Thimbles: Protecting Critical Connection Points

Thimbles are essential yet often overlooked components in marine rope systems. These metal inserts protect rope eyes at connection points, increasing service life.

Stainless steel thimbles used in marine environments offer high corrosion resistance and strength. The correct size must match rope dimensions and operational needs to prevent stress points. Quality thimbles have rounded edges to protect fibers.

Proper selection requires matching the inside diameter to rope size and intended use. Oversized thimbles allow harmful rope movement, while undersized ones create dangerous stress points.

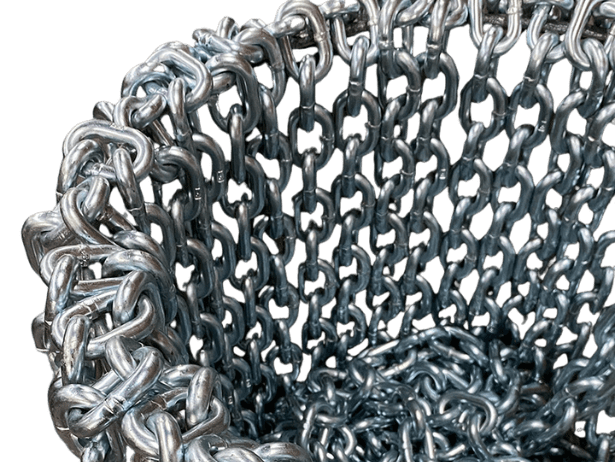

Shackles and Connection Hardware

The connection point between rope and other components is often the system’s weakest area. Reliable connections and simple assembly make quality shackles essential for load-bearing applications.

Marine-grade stainless steel shackles provide the optimal blend of strength, corrosion resistance, and long service life. Anchor shackles offer maximum strength for critical connections, while chain shackles fit better in confined spaces.

Selecting the correct shackle requires understanding working load ratings and safety factors. Marine shackles should have a breaking strength at least four times the maximum expected working load.

Snubbers and Shock Absorbers

Dynamic forces in marine environments create excessive stress on dock lines and hardware. Snubbers and shock absorbers help reduce peak loads, protect crew, and extend equipment life.

Nylon snubbers stretch under load to absorb shock.Their design allows controlled extension that reduces forces on dock lines and cleats.

Rubber shock absorbers provide consistent performance across temperature ranges while maintaining durability. They work best in confined installation areas.

Fairleads and Guides

Fairleads and guides direct rope along the correct path, prevent kinking, and reduce drag for smooth operation under load. Proper routing prevents damage and maintains efficiency.

Stainless steel fairleads made from marine-grade materials provide strength and corrosion resistance. Their polished surfaces reduce friction while withstanding heavy loads.

Roller fairleads in applications with frequent line movement significantly reduce both friction and rope wear. High-quality models feature sealed bearings to block saltwater intrusion.

Cleats and Attachment Points

The reliability and safety of dock lines and mooring systems depend on the quality of cleats and mounting hardware. Professional installations require hardware that exceeds design loads and includes safety margins.

Marine-grade stainless steel cleats provide excellent strength and corrosion resistance. Selecting the correct cleat size ensures a secure grip and proper rope support.

Backing plates and through-bolts with appropriate sealants keep cleats firmly attached under load. Undersized mounting hardware causes failures even when the rest of the system is well designed.

End Protection and Whipping

Protecting rope ends prevents unraveling and creates a professional finish. End treatments extend rope life and can assist with identification.

Hand whipping with marine-grade twine effectively protects rope ends while preserving a traditional appearance. Proper technique prevents movement or loosening over time.

Heat sealing prevents fraying in synthetic ropes. While fast, it provides only short-term durability in harsh environments.

Selection Criteria for Marine Accessories

Selecting accessories requires understanding application needs and environmental effects.

Accessories must work with rope materials and construction techniques. Mixing incompatible metals can cause galvanic corrosion, and unsuitable plastic materials can degrade rope fibers.

All accessories must support working loads at specified values and include safety factors. Weak accessories create vulnerabilities that can lead to system failure.

Marine accessories must withstand UV exposure, saltwater corrosion, and temperature changes.

Conclusion

Basic rope installations become professional marine systems through essential accessories that enhance reliability, improve safety, and extend service life. Dock lines and rope systems perform at their best when supported by chafe protection and secure connection hardware.

Investing in quality accessories from American Rope leads to longer equipment life, better safety performance, and lower maintenance needs. Professional rope manufacturers like American Rope provide modern accessory solutions and expert guidance. Marine systems that combine high-quality ropes with suitable accessories achieve longer operational periods while meeting safety standards.