As the boating season winds down, many boat owners focus on engine winterization, hull cleaning, and covering their vessels for storage. However, one critical maintenance task is often overlooked: comprehensive rope assessment. The end of the season provides an ideal opportunity to inspect, evaluate, and replace marine lines before storage, ensuring your vessel begins next season with reliable equipment. At American Rope, we help boat owners understand what to look for during year-end inspections and when replacement becomes necessary rather than optional.

Why Year-End Assessment Matters

Throughout the boating season, dock lines, anchor rodes, and fender lines endure constant stress from UV exposure, saltwater immersion, abrasion against hardware, and repeated loading cycles. Damage accumulates gradually, often in ways that are not apparent during casual observation. A year-end assessment, when lines are removed and cleaned, reveals wear patterns and damage that could lead to failures next season.

Marine rope suppliers like American Rope recommend systematic end-of-season inspections for all critical rope systems. This timing allows adequate lead time to order replacements, schedule custom fabrication, and ensure new equipment arrives before spring commissioning begins. Waiting until launch day to discover damaged lines often leads to rushed decisions and potential compromises in quality or proper sizing.

Dock Line Inspection Protocol

Begin your assessment by removing all dock lines from the vessel and laying them out in a clean, well-lit area where you can examine their entire length systematically.

Visual Inspection: Walk the length of each line and look for obvious damage, including fraying, broken fibers, discoloration, or changes in diameter. Pay close attention to high-stress areas where lines contact cleats, chocks, and dock hardware. American Rope’s double braid dock lines should maintain a consistent diameter and smooth outer jacket throughout their length. Variations indicate internal damage or cover slippage that compromises strength.

Tactile Assessment: Run your hands along the entire line, feeling for soft spots, hard areas, or stiff sections that indicate internal damage. Double braid rope should maintain consistent flexibility throughout. Hard spots often indicate heat damage from friction, while soft areas suggest core failure or separation between the core and cover.

Eye Splice Examination: Inspect eye splices carefully for pulled stitching, elongation, or separation. The splice throat area experiences the highest loads and often shows wear before other sections. Check whipping at splice throats and bitter ends for looseness or deterioration. American Rope’s professional whipping should remain tight and secure after a full season of use

Anchor Rode Evaluation

Anchor rodes face unique stresses, including bottom abrasion, debris contact, and extreme loading during storm conditions. A comprehensive assessment requires examining both rope and chain components.

Rope Section Inspection: The first 50 to 100 feet of anchor rode, which regularly contacts the bottom, experiences the most severe abrasion. Look for fuzzy or worn areas, reduced diameter, or stiffening that indicates sand or mud penetration into the rope structure. American Rope’s three-strand and double braid anchor rodes should maintain their original suppleness. Stiff sections indicate the rope has reached the end of its service life.

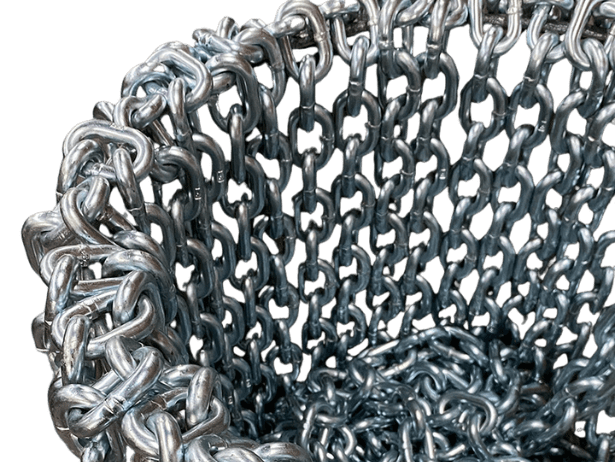

Chain Assessment: Examine anchor chain links for elongation, deformation, or cracks. Check the condition of the galvanizing and look for areas where the zinc coating has worn through to bare steel. Rust indicates compromised protection and suggests chain replacement should be considered. Inspect the rope-to-chain splice connection carefully, ensuring the splice remains secure and the transition area shows no excessive wear.

Hardware Evaluation: Check shackles, swivels, and connection hardware for wear, corrosion, or deformation. These components often fail before the rope or chain yet receive less attention during inspections. Replace questionable hardware before it fails and damages other ground tackle components.

Fender Line Assessment

Fender lines may seem less critical than dock lines or anchor rodes, yet their failure can result in expensive gelcoat damage or worse.

Abrasion Points: Examine areas where fender lines contact cleats, rails, or other hardware. These high-friction zones often show wear before other sections. American Rope’s fender lines feature professional splicing that should maintain integrity throughout the season. Look for pulled stitching or elongated eyes that indicate overloading.

UV Damage Indicators: Fender lines often remain exposed to direct sunlight more consistently than other rope applications. Check for fading, surface powdering, or brittleness that indicates UV degradation. Solution-dyed rope from American Rope resists color change better than dyed-after-manufacture alternatives, but all synthetic rope eventually shows UV effects.

Documentation and Record Keeping

Create detailed records of your year-end assessment, including installation dates, inspection findings, and replacement recommendations. This documentation helps track rope service life and plan future replacements.

Photo Documentation: Photograph questionable areas that show wear patterns, damage, or deterioration. These images provide baseline references for tracking degradation and are useful when consulting marine rope suppliers about replacement needs.

Service Life Tracking: Note when each rope was installed and calculate total service time. Most dock lines and anchor rodes should be replaced every three to five years, regardless of apparent condition, as UV degradation and internal fatigue occur even in well-maintained rope.

Cleaning Before Storage

Proper cleaning removes salt crystals, biological growth, and embedded contaminants that accelerate degradation during storage.

Freshwater Rinse: Thoroughly rinse all rope with fresh water, paying special attention to eye splices and high-stress areas where salt concentration tends to be highest. Allow lines to dry completely before storage. American Rope’s marine-grade construction resists mold and mildew, but storing wet rope in closed containers encourages biological growth.

Deep Cleaning When Needed: Heavily soiled lines benefit from soaking in fresh water with a mild marine soap. Avoid harsh detergents or bleach, which can damage nylon fibers. Gentle agitation helps remove embedded contaminants without stressing the rope structure.

Replacement Planning

Year-end assessment often reveals rope that requires replacement before next season. Planning these purchases now allows for thoughtful decisions rather than rushed spring orders.

Custom Fabrication Lead Times: American Rope’s custom dock lines, anchor rodes, and specialized assemblies require fabrication time. Ordering during the off-season helps ensure delivery before spring commissioning begins. Work with our team to specify exact lengths, eye sizes, colors, and hardware configurations for your vessel.

Budget Allocation: Identifying replacement needs during year-end assessment allows rope purchases to be incorporated into annual maintenance budgets. Replacing lines systematically over multiple years helps prevent large, unexpected expenses.

Making the Smart Choice

Year-end rope assessment is an investment in safety and reliability that pays dividends throughout the next boating season. Comprehensive inspection reveals developing problems before they become dangerous failures, while proper storage preparation extends rope service life. Working with experienced marine rope suppliers like American Rope ensures you receive expert guidance on inspection techniques, replacement timing, and appropriate specifications for new equipment. The time invested in a thorough year-end assessment ensures your vessel begins next season with rope systems you can trust when conditions challenge their performance.