When selecting the right chain for marine, industrial, or other demanding applications, the choice often comes down to stainless steel or galvanized steel. While both types are durable and reliable, they have key differences that make them better suited for specific environments and uses. Understanding these differences is essential for selecting the chain that best meets your specific needs.

Stainless Steel Chain

Stainless steel chains are valued for their resistance to corrosion and long-lasting durability in harsh environments. Here’s what sets them apart:

- Corrosion Resistance: Stainless steel is highly resistant to rust and corrosion, making it ideal for marine environments where chains are exposed to saltwater, moisture, and humidity. It performs well in wet or acidic conditions without the need for coatings or treatments.

- Aesthetic Appeal: Stainless steel has a naturally shiny, polished finish often preferred for applications where appearance matters, such as decorative projects or visible installations on boats or docks.

- Strength and Durability: While stainless steel is strong, it can be slightly less tough than galvanized steel when comparing chains of the same thickness. However, its superior resistance to environmental damage makes it a better long-term investment for coastal or extreme environments.

- Cost: One of the drawbacks of stainless steel is its higher cost. It tends to be more expensive than galvanized chain, but the longevity and low maintenance costs often justify the investment in situations where corrosion resistance is critical.

Galvanized Steel Chain

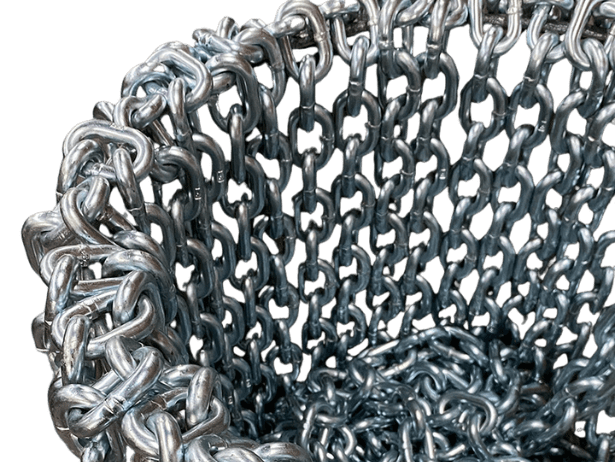

Galvanized steel chains are coated with a layer of zinc to protect against corrosion, making them widely used across various industries. Here are several advantages they offer:

- Corrosion Protection: The zinc coating provides protection against rust, although it’s less effective in extreme saltwater environments compared to stainless steel. Over time, the galvanized coating can wear down, especially with constant moisture exposure. Despite this, galvanized chains are commonly used in marine applications when properly maintained.

- Strength: Galvanized steel is known for its high strength and durability, making it ideal for heavy-duty tasks such as towing, lifting, or anchoring. It can handle significant loads, making it a popular choice in industrial, construction, and agricultural settings.

- Cost-Effective: Galvanized chain is typically more affordable than stainless steel. For many applications, the lower cost combined with adequate rust resistance makes it a practical choice, especially in environments where the chain is not exposed to saltwater or extreme moisture for extended periods.

- Maintenance: Unlike stainless steel, galvanized steel chains may require more frequent inspections and maintenance to ensure the zinc coating remains intact. In harsh conditions, the coating can wear off, leading to potential rusting if not monitored.

Key Considerations for Choosing the Right Chain

When deciding between stainless steel and galvanized chain, consider the following factors:

- Environment: If you’re working in a marine or highly corrosive environment, stainless steel is the better choice for its superior corrosion resistance. In less extreme conditions, such as freshwater or outdoor use with occasional exposure to moisture, galvanized steel may be sufficient.

- Budget: Stainless steel is more expensive, so if cost is a major concern and the chain won’t face harsh conditions, galvanized steel can provide good performance at a lower price.

- Strength Requirements: If strength is your primary concern and you need a chain for heavy lifting or industrial use, galvanized chains are typically tougher. However, stainless steel chains can still handle significant loads while offering corrosion resistance.

- Aesthetic Needs: If the chain will be visible or part of a decorative application, stainless steel’s shiny, polished look may be preferred over the duller finish of galvanized steel.

Applications for Each Chain

- Stainless Steel Chain:

- Marine environments

- High-humidity areas

- Decorative applications

- Food processing and medical industries (due to its hygienic properties)

- Galvanized Steel Chain:

- Construction

- Industrial lifting and towing

- General outdoor use

- Agricultural applications

- Marine environments (with proper maintenance)

Conclusion

Both stainless steel and galvanized chains serve important roles across various applications. By considering factors such as environment, budget, strength requirements, and aesthetic considerations, you can make an informed decision that meets your needs. For those prioritizing long-term durability and corrosion resistance, stainless steel is the best choice. Conversely, if cost-effectiveness and strength are your primary concerns, galvanized steel is often sufficient. At American Rope, we provide a wide range of chain options to suit any need—whether you’re securing your vessel, lifting heavy loads, or simply looking for a reliable chain solution.