In the demanding world of marine operations, efficiency and safety depend on proper line management. Whether you’re managing a commercial vessel, operating a fishing boat, or maintaining a luxury yacht, the ability to quickly identify and organize lines can mean the difference between smooth operations and costly delays. One technique transforming line management is color-coded whipping, which combines traditional rope finishing with modern organizational strategies to improve efficiency.

Understanding Whipping: The Foundation of Professional Line Management

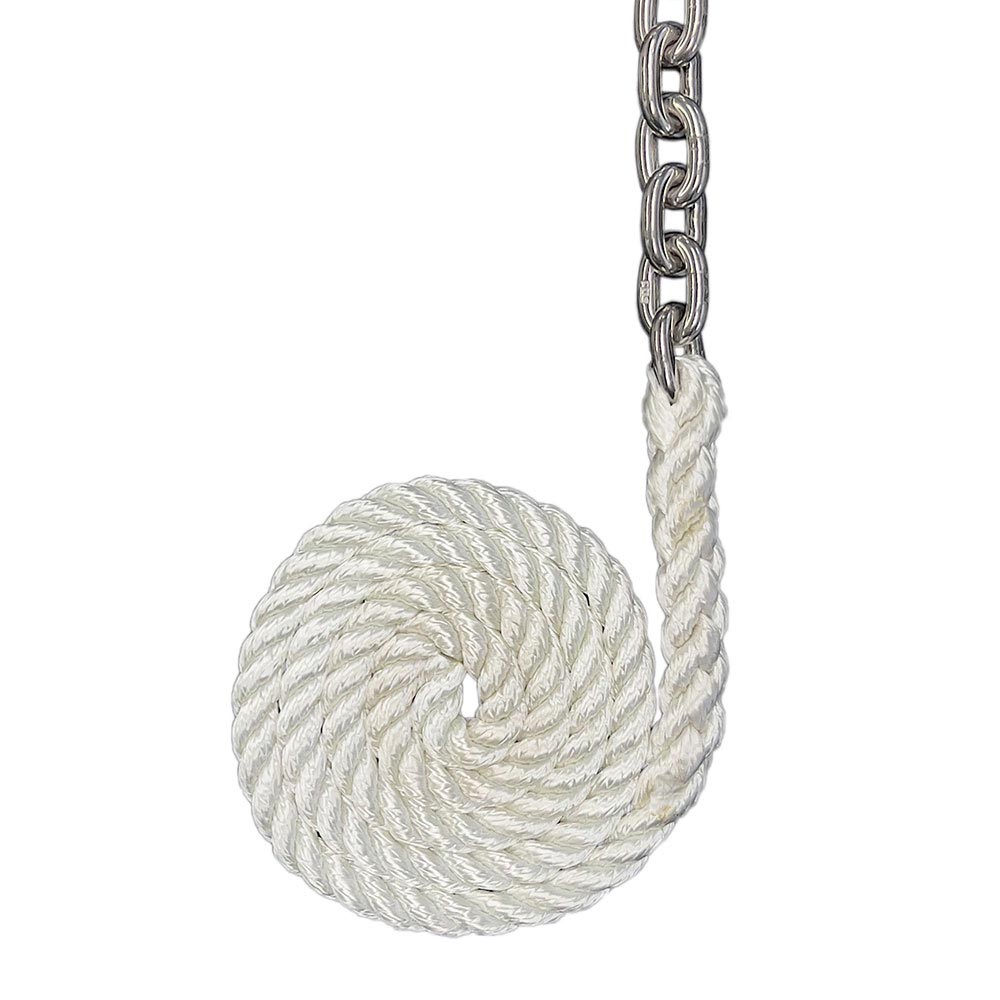

Whipping is the long-standing practice of binding the end of a rope with twine or thread to prevent fraying and unraveling. Mariners have used this method for centuries as both a practical necessity and a sign of professional seamanship. For American Rope’s double braid nylon rope, widely used in marine applications for its high strength-to-weight ratio and excellent stretch characteristics, proper whipping is critical.

Traditional whipping prevents core and jacket separation, maintains structural integrity under load, and provides a clean finish that reflects professional standards. Color-coded whipping builds on these benefits by turning a maintenance practice into an organizational tool.

The Color-Coding Revolution

Color-coded whipping transforms ordinary line finishing into a sophisticated organizational system. By using different colored whipping twine for various types of lines, marine professionals can instantly identify the purpose, length, or designated use of any rope in their inventory. This system becomes particularly valuable when working with marine rope suppliers who offer standardized color-coding options or when establishing consistent protocols across multiple vessels.

The most common color-coding applications include:

Functional Identification: Different colors designate specific line functions: blue for bow and stern lines, red for spring lines, green for fender lines, and yellow for anchor lines. This system allows crew members to grab the correct line instantly, even in low-light conditions or during high-stress situations.

Length Classification: Many operations use color coding to indicate rope lengths. For instance, 15-foot lines might feature red whipping, 20-foot lines blue, and 25-foot lines green. This system eliminates guesswork when selecting appropriate line lengths for specific docking situations.

Load Capacity Indication: Color-coded whipping can also indicate the working load limit of different lines, with specific colors representing different strength categories. This application is particularly valuable for operations using multiple rope types and sizes.

Implementation in Modern Marine Operations

The implementation of color-coded whipping requires careful planning and consistent execution. Professional rope manufacturers like American Rope have recognized this trend and now offer pre-whipped lines with standardized color coding, ensuring consistency across maritime operations.

When establishing a color-coding system, several factors must be considered:

Crew Training: All personnel must understand the color-coding system thoroughly. This includes not only knowing what each color represents but also understanding the importance of maintaining the system through proper storage and handling procedures.

Standardization: Consistency is crucial. Once a color-coding system is established, it must be applied uniformly across all lines and maintained over time. This includes ensuring that replacement lines follow the same coding standards.

Documentation: Maintaining clear documentation of the color-coding system helps ensure continuity, especially when new crew members join the operation or when lines are replaced or repaired.

Technical Considerations for Double Braid Nylon Applications

Double braid nylon rope presents unique considerations for color-coded whipping. The construction of double braid rope, with its inner core and outer jacket, requires specific whipping techniques to ensure the color-coded system remains effective throughout the rope’s service life.

The sailmaker’s whipping is often preferred for double braid construction because it penetrates between the strands of the outer jacket, creating a more secure bond than simpler whipping techniques. When applying colored whipping to double braid rope, the technique must account for the rope’s construction to prevent slippage and ensure longevity.

Professional installation of color-coded whipping on double braid nylon requires attention to:

Tension Control: Proper tension during whipping ensures the colored thread won’t slip or loosen over time, maintaining the visual identification system’s effectiveness.

Thread Selection: Marine-grade whipping twine must resist UV degradation, saltwater exposure, and abrasion. Inferior materials can fade or break, compromising the identification system.

Finishing Techniques: Proper finishing, including burning or binding the whipping ends, ensures durability in marine environments.

Benefits Beyond Organization

Color-coded whipping offers advantages that extend well beyond simple organization. In commercial operations, the time saved by instantly identifying the correct line can translate to significant cost savings, particularly in busy ports where vessel turnaround time directly impacts profitability.

Safety improvements are equally significant. In emergency situations, the ability to quickly identify and deploy the appropriate line can be crucial. Color-coded systems reduce the cognitive load on crew members, allowing them to focus on safe execution rather than line selection.

Maintenance benefits are also considerable. Color-coded systems make it easier to track line usage, rotation schedules, and replacement needs. This systematic approach helps ensure that lines are replaced before they reach the end of their safe service life.

Integration with Modern Marine Equipment

Today’s marine operations increasingly rely on integrated systems, and color-coded whipping fits seamlessly into modern equipment configurations. Boat dock lines with color-coded whipping integrate well with modern cleating systems, winches, and storage solutions.

The system also complements electronic inventory management, where color codes can be linked to digital records tracking purchase dates, inspection schedules, and performance history.

Future Developments and Innovations

The evolution of color-coded whipping continues with advances in materials and techniques. New synthetic threads offer improved UV resistance and color stability, while advanced whipping machines allow for more precise and consistent application.

Some operations are experimenting with additional identification methods, such as incorporating reflective threads for improved visibility in low-light conditions or using specialty threads that change color when exposed to excessive heat or chemical contamination.

Conclusion

Color-coded whipping blends traditional seamanship with modern efficiency, offering clear advantages in safety, organization, and professionalism. For operations using double braid nylon rope, it provides a reliable system that improves both performance and presentation.

As marine operations become more complex and safety-focused, adopting standardized systems like color-coded whipping is not only beneficial but essential. With American Rope’s commitment to quality manufacturing and customer support, implementing this system is both practical and reliable.

The return on investment is clear: greater efficiency, stronger safety margins, and a professional appearance that reflects well on any vessel. In an industry where every second matters, color-coded whipping turns line management into a true operational advantage.

FAQs

What is color-coded whipping?

Color-coded whipping is a professional rope-finishing technique that combines traditional whipping (binding rope ends with twine to prevent fraying) with modern organizational strategies. By using different colored marine-grade twine for different lines, mariners can instantly identify a rope’s specific purpose, length, or load capacity without having to measure or inspect it manually.

How does color coding help organize boat lines?

Color coding streamlines marine operations by providing instant visual identification. This is particularly valuable in high-stress or low-light situations, allowing crew members to grab the correct line immediately. It eliminates guesswork regarding which lines are designated for the bow versus spring positions and helps categorize inventory by length or strength.

What colors are standard for dock lines vs. anchor lines?

While many boaters develop their own systems, the most common professional color-coding applications include:

- Blue: Bow and stern lines.

- Red: Spring lines.

- Green: Fender lines.

- Yellow: Anchor lines. Additionally, colors are frequently used to classify lengths (e.g., Red for 15-foot lines, Blue for 20-foot lines, and Green for 25-foot lines).

Can I customize whipping colors for my fleet?

Yes. Professional rope manufacturers like American Rope allow for full customization of whipping colors. This enables fleet managers or private owners to establish their own consistent protocols across multiple vessels, ensuring that every replacement line follows the same documented standard for their specific operation.

How long does colored whipping last in saltwater?

The longevity of colored whipping depends on the material and installation technique. American Rope uses marine-grade whipping twine that is specifically engineered to resist UV degradation and saltwater exposure. When applied using a Sailmaker’s whipping (which involves stitching through the rope strands), the colored twine creates a permanent bond that maintains its structural integrity and color throughout the rope’s service life.